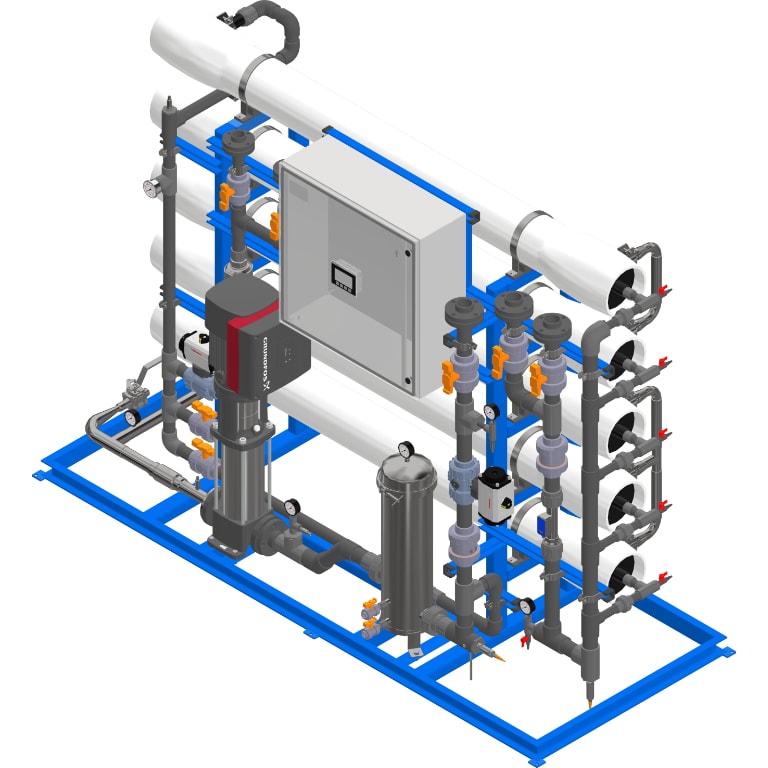

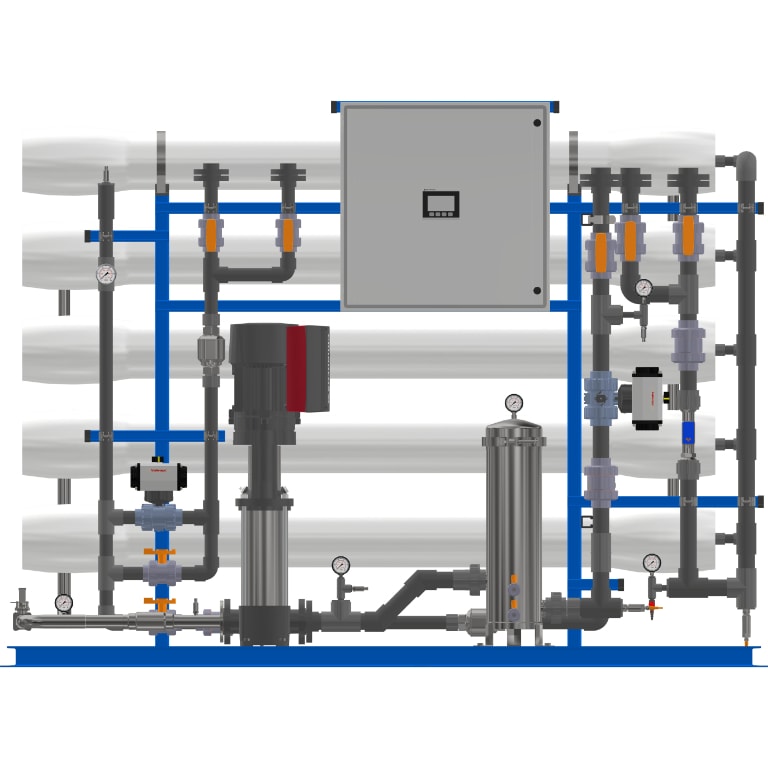

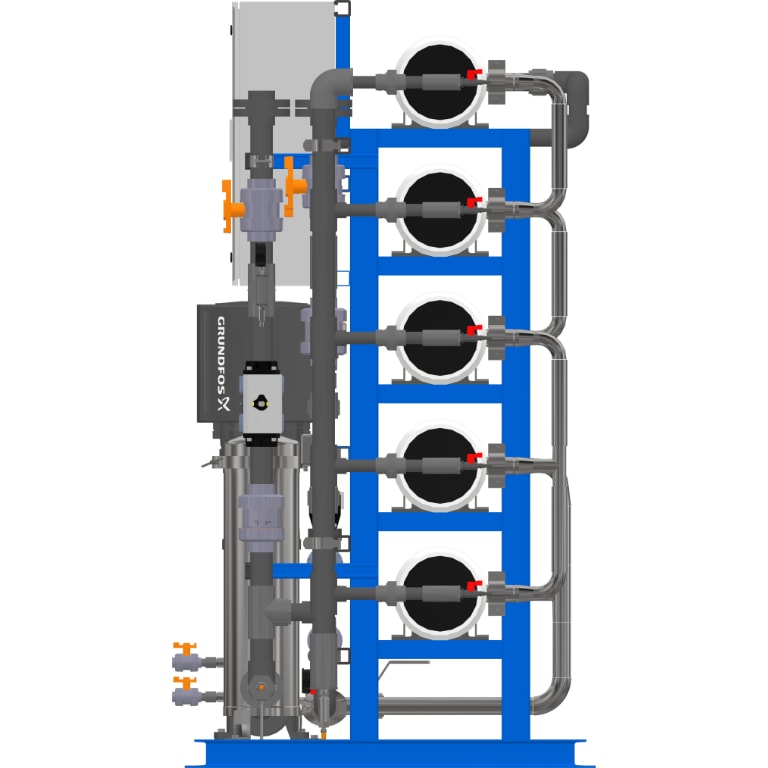

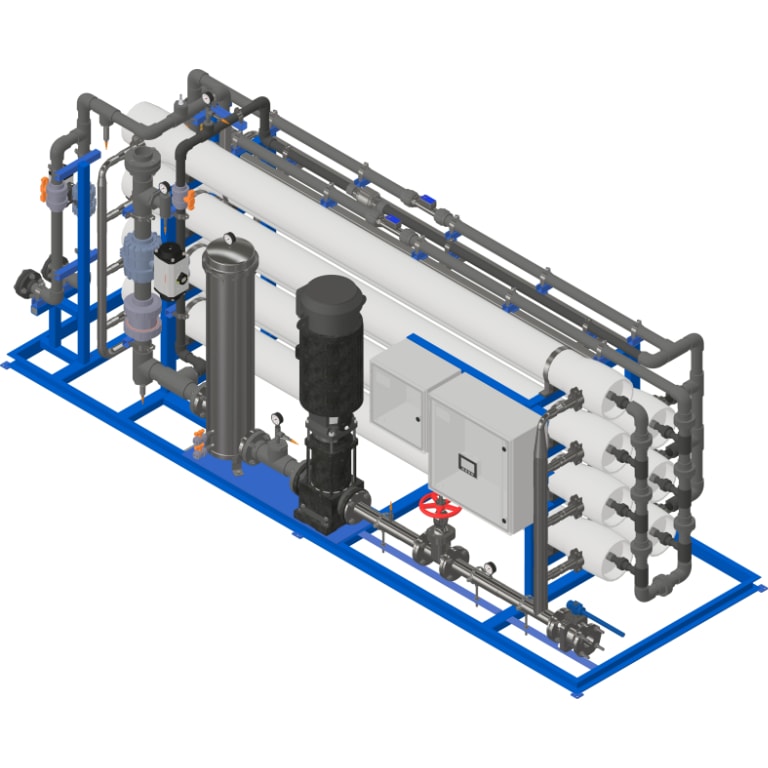

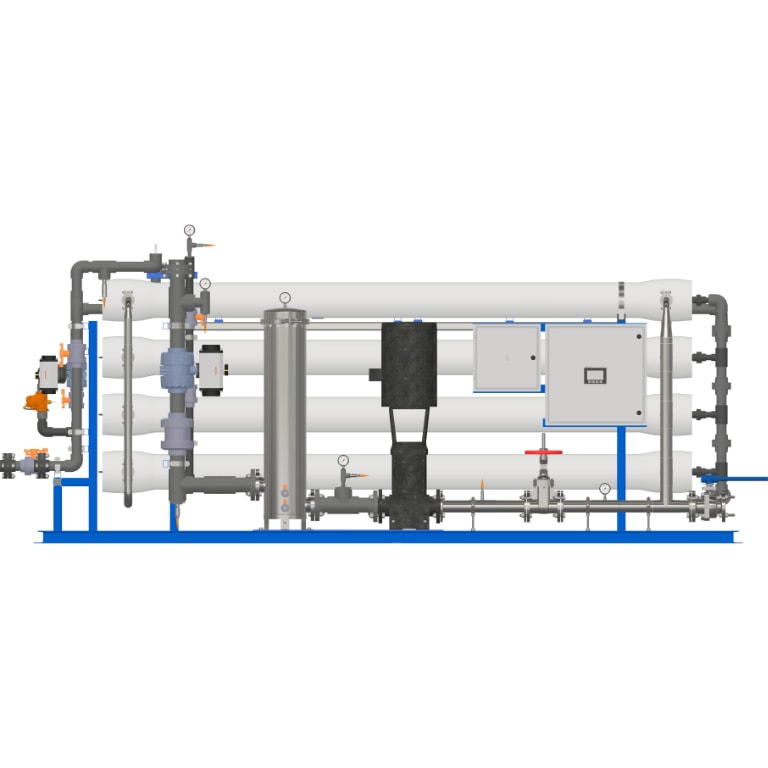

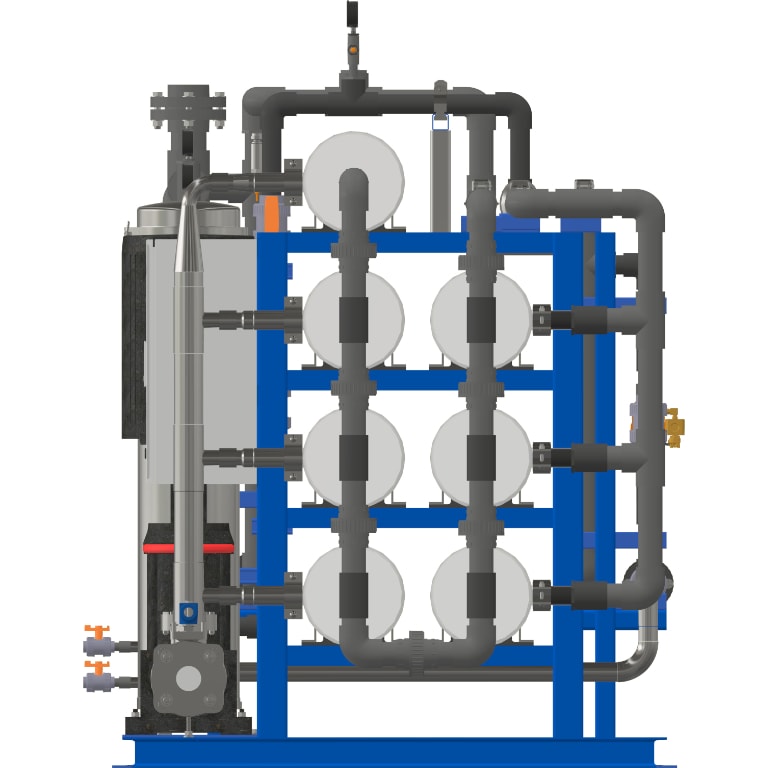

Industrial Reverse Osmosis Systems

Industrial Reverse Osmosis

Excalibur Water Systems Industrial Reverse Osmosis Systems are a highly effective water treatment process that can reduce up to 97-99% of total dissolved solids for industrial process water applications.

An industrial reverse osmosis system is utilized in processes including food & beverage, power generation, boiler feeds, oil & gas production, high-purity water generation, central sterilization, and manufacturing processes.

Controlled utilizing PLC with touch screen HMI, pneumatic or motorized valves with limit switch, magnetic and ultrasonic flow meters, pressure transducers, conductivity, pH instrumentation, high-pressure stainless-steel pressure pump with 5-micron sediment turbidity filtration, TFC membranes application based, with high recovery designs.

Industrial Reverse Osmosis Industry Applications:

- Boiler Feed / Makeup Water

- Cooling Tower

- Mining

- Power Generation

- Laboratories

- Manufacturing Process Water

- Chemical Process Water

- Pharmaceutics

- Photographic Processing

- Printing

- Dairy

- Ice Making

- Humidification

- Drinking Water

- Cosmetics

- Food and Beverage Processing

- Vehicle Washing

- Horticulture

- Electronics

- Metal Finishing