Commercial Cooling Tower Side Stream Filters

Contact Us

Questions about Excalibur Commercial Water Treatment Solutions and Products?

If you would like more information or to request a free quote, please click the button below. You can also contact us by phone or email:

1-877-733-8999

[email protected]

Overview

Cooling towers are excellent air scrubbers. High volumes of air pass through the tower subjecting components to airborne contaminants. Concentrated make-up water can also contribute to a build-up of contaminants on the cooling tower distribution and fill areas which eventually flake off and become suspended in the recirculating water.

Improving the water quality in the cooling loop is a simple, cost-effective method of realizing efficiency gains. Many contaminants cannot be seen by the visible eye, and collectively they can lead to system inefficiencies, increased microbiological growth, and excessive corrosion. Suspended solids result in water with high turbidity, which can foul heat exchange surfaces. Under high flow conditions, the suspended solids can also be abrasive and cause excessive wear of pump seals and valves and erosion of pipes.

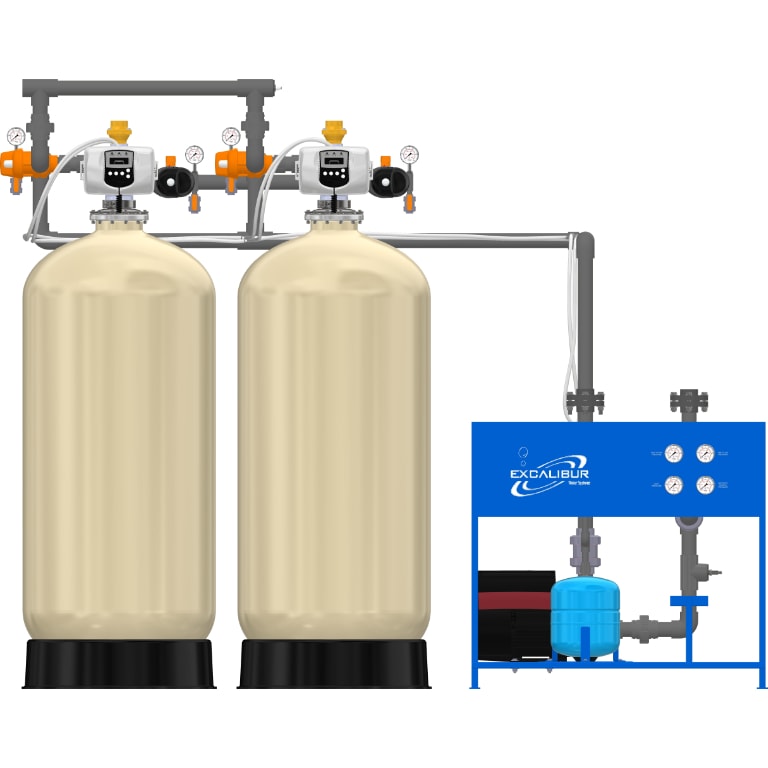

Excalibur Water Systems offers proven industry-known cooling tower side stream turbidity filters for your commercial cooling tower operation applications. We offer turbidity filtration in simplex or multi-tank models and designs with user-friendly electronics and trouble-free operation.

These systems offer a separate source feed line for regeneration triggered by a differential pressure drop across the filter, pre-set determined number of gallons or days override. A booster pump is incorporated in the design to boost the cooling tower water to be filtered as well as the separate source to ensure proper flow designs and minimum required regeneration pressures.